CNC Machining

In the past I have had three different CNC machines. Starting with a very basic, mainly home-made machine with a relatively small footprint. This was a good starting point, as it proved that even a very basic setup could give reasonable results.

The second machine featured a larger machining area and was the basis for the third and current setup, having had aluminium profiles as the main construction along with ‘proper’ CNC movement hardware.

Based around the popular Chinese-manufactured 6040 machine which was purchased with only the mechanical parts and didn’t include the motion hardware and controller, as these were migrated from the previous machine. Whilst these Chinese-supplied machines are often dismissed due to quality, I have been more than satisfied with the capabilities of a relatively inexpensive setup.

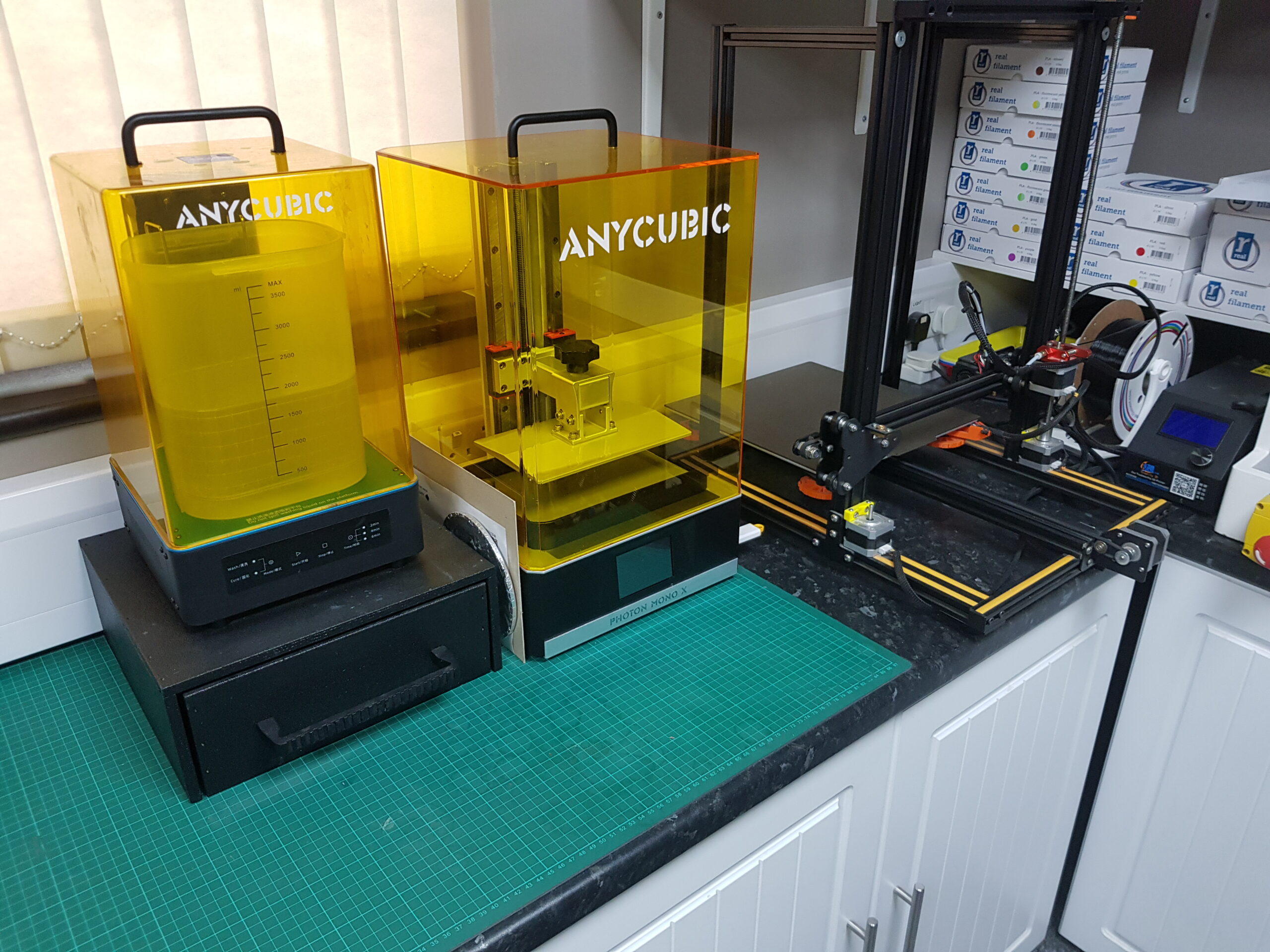

3D Printing

See what 3D printers I use and how I do it.

The Mono X is a UV photocuring LCD type device, using resin as the printing medium and a large build volume of 192 mm x 120 mm x 245mm, the 4k screen resolution produces incredibly detailed parts. The detail obtained by this machine, especially for the low cost is remarkable.

Parts are designed in a 3D CAD program and saved as an STL (Stereo Lithography) file and then imported into the printer’s supplied ‘splicer’ program. This splicing software converts the file into the layers required for printing.

As a rule, supports are required when printing with any 3D printer. These supports are generated automatically by the splicing software but can be manually adjusted if necessary. Supports are sacrificial, meaning that they are easily removed when the printing is completed.

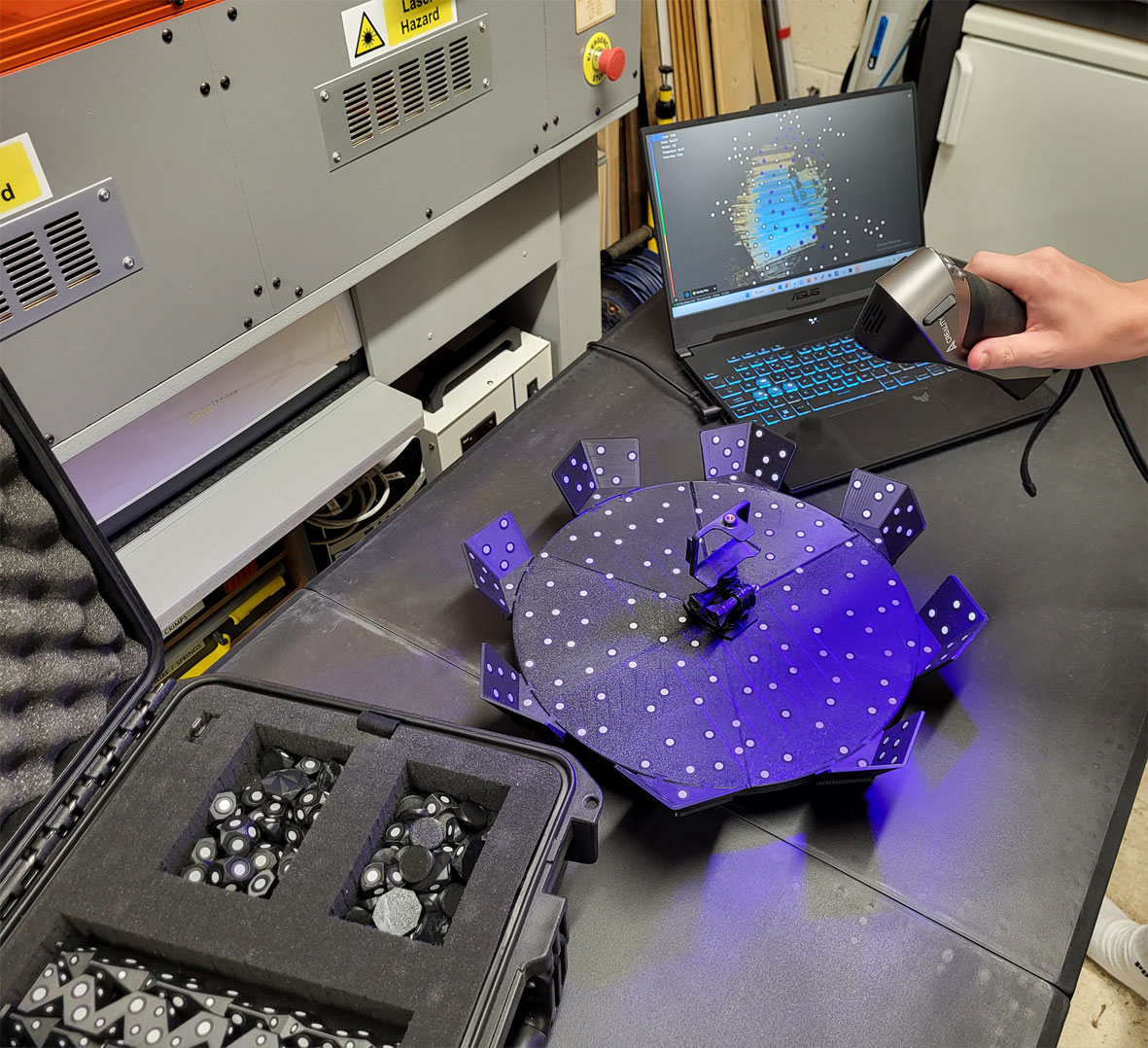

3D Laser Scanning

I recently invested in a 3D laser scanner, as this technology has come on leaps and bounds over the last couple of years or so. The price of high quality 3D scanners, irrespective of the type, has improved greatly and continues to do so at an alarming rate.

I opted for the Creality Raptor system, although there are numerous manufacturers to chose from. The Raptor includes a combination of NIR (near Infra Red) and Laser scanning modes, the latter of which produces almost metrology-grade scans, with a resolution of up to 0.1mm.

Most 3D scanners, if not all, work on the same principle, by projecting a beam (or multiple beams) of light onto the object being scanned. These beams produce a huge quantity of points in space (known as a Point Cloud). Depending on the size of the object and the selected resolution, tens of thousands or even more than a million points can be produced. This might not be the most technically accurate description….

Model Showcase

About Me

I have quite a few interests but my hobby is making model trucks. Other interests include technology, heavy engineering, robotics and anything CNC-related.

Useful Links

Copyright 2025 - Scale Model Trucks